Production: Planned, Controlled, and Efficient Manufacturing

Production Management in Zventory ERP provides an integrated and structured framework to plan, execute, monitor, and control manufacturing operations with precision. It bridges the gap between inventory, procurement, and dispatch, ensuring smooth production flow with complete material and process visibility.

The module enables creation and management of production orders, linked directly to Bills of Materials (BOM), routing, and work stages. Before execution, Zventory validates raw material availability, batch/lot details, and expiry constraints to prevent production delays or quality risks. Materials can be allotted directly from inventory to production, ensuring accurate consumption tracking and real-time stock updates.

During production, the system captures stage-wise progress, material consumption, wastage, rework, and output quantities. This ensures precise cost tracking, improved yield analysis, and transparency across production cycles. Finished and semi-finished goods are automatically recorded into inventory with full traceability, including manufacturing dates, batch numbers, and quality status.

Zventory Production Management supports multi-branch and multi-unit operations, allowing centralized planning with localized execution. Approval workflows, role-based access, and audit logs ensure controlled operations and compliance with internal and external standards.

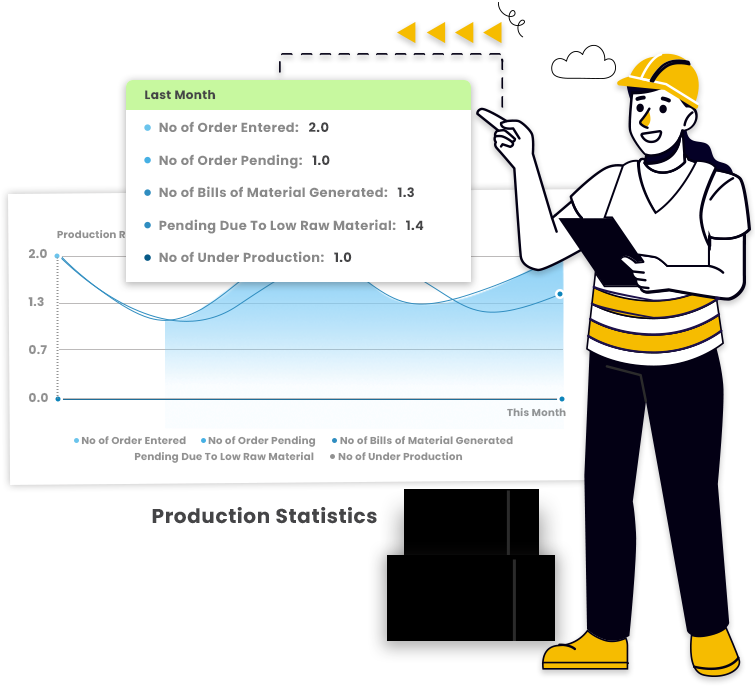

With real-time dashboards and analytical reports, management gains insights into production efficiency, bottlenecks, resource utilization, and variance analysis. This enables data-driven decisions to optimize capacity, reduce waste, and improve on-time delivery.

Overall, Production Management in Zventory ERP transforms manufacturing into a controlled, efficient, and insight-driven process, supporting scalability and operational excellence.

- BOM Generation

- Managing All Production (Pending, Running, Completed)

- Indent Purchase Requisition